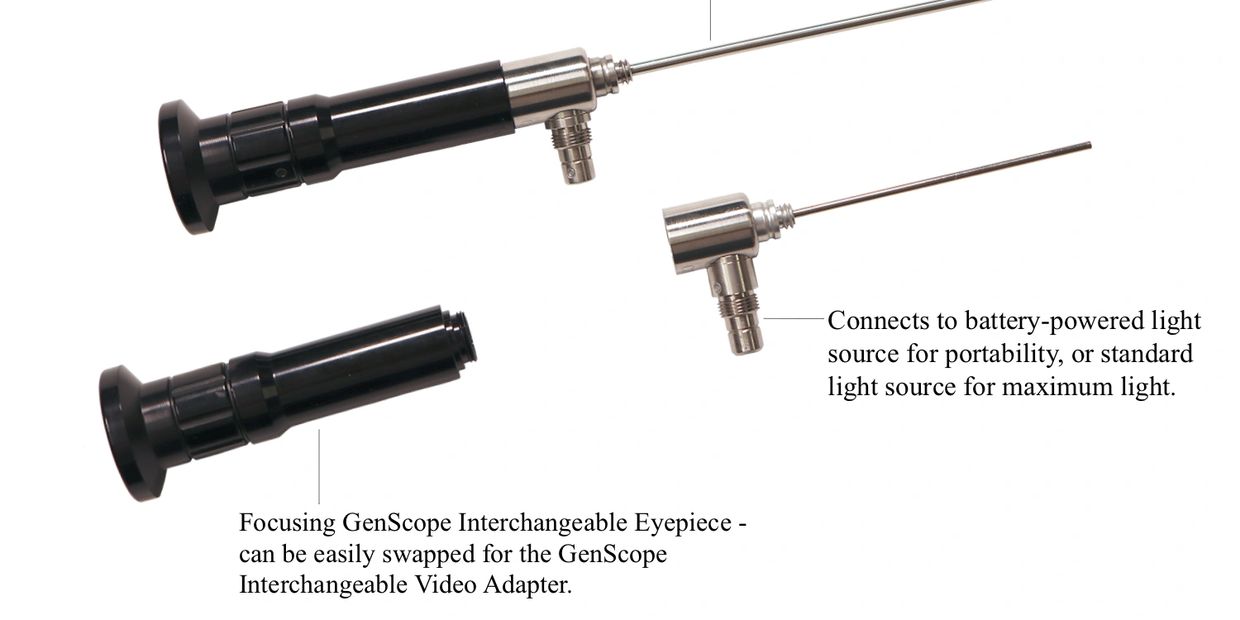

GenScope’s Micro-Diameter Rigid Borescopes are engineered for unmatched image clarity in the smallest inspection spaces. Built with a durable stainless-steel probe, they deliver stability, reliability, and exceptional visual accuracy in demanding industrial and medical environments. Rigid scopes contain a solid glass rod lens that runs the entire length of the probe, providing the clearest image possible. Each scope is also equipped with a precision focusing GenScope eyepiece, which can be easily swapped with a video adapter for a screen-view. For illumination, the MicroRigid line supports both portable battery-powered light sources for field use and high-intensity standard light sources for maximum brightness in controlled settings.

Key Features:

- Micro-Diameter Design: Available in sizes from 1.3 mm to 3.0 mm for access into ultra-small inspection paths.

- Rigid Stainless-Steel Probe: Provides stability, straight-line access, and robust durability in demanding environments.

- High-Resolution Imaging: The glass lens provides a brighter and clearer high-resolution image..

- Focusing Eyepiece: Includes an adjustable GenScope eyepiece for precise focus control.

- Interchangeable Video Adapter: Eyepiece can be replaced with a camera adapter for digital viewing.

- Light Source Versatility: Compatible with portable battery-powered light sources or standard high-intensity light sources.

- Two view directions: Straight and Right Angle.

Applications:

- Aerospace: Internal inspection of turbine blades, fuel nozzles, and precision-engineered components.

- Medical & Dental Device Manufacturing: Evaluation of fine internal channels and surgical instrument assemblies.

- Precision Engineering: Quality control of machined parts, internal cavities, and micro-mechanical systems.

- Automotive & Engines: Inspection of injectors, combustion chambers, and internal engine components.

- Research & Development: Detailed visualization for prototype testing and micro-assembly analysis.

Ideal Use Cases:

These are the inspection tasks where the MicroRigid’s ultra-thin, precision-crafted design provides unique advantages.

- Small Machine Nozzles & Micro-Passages

Reaches extremely small openings where even flexible micro scopes may be too delicate.

- Precision CNC & Machined Part Inspection

Ideal for checking internal dimensions, burrs, and machinist-quality features.

- Injector, Carburetor & Fuel System Channels

Perfect for tight, straight channels requiring high optical clarity.

- Medical Device Manufacturing (Non-Clinical)

Great for lumen verification, micro-channel inspection, and quality control of precision components.

- Semiconductor & Electronics Equipment

Useful for inspecting micro-cavities, housings, and tooling where rigidity ensures stability.

Bottom Line:

When the job requires high-resolution inspection through extremely small and straight openings, the MicroRigid is the most precise tool available.

Are you unsure of what you need? GenScope specialists work with you to identify your specific needs and develop a personalized solution. Reach out by clicking the 'Contact Us' button, then leave the rest to us.